In food processing, the way a product is cut plays a crucial role in its final quality and market appeal. Slicing and dicing are not just preparation steps; they directly influence cooking time, texture, presentation, and even taste. Uniform cuts ensure consistent cooking, better portion control, and improved visual appeal, which is especially important for packaged and ready-to-cook foods.

As consumer demand for clean, ready-to-use, and visually appealing food products continues to grow, food processors are increasingly investing in advanced cutting solutions.Efficient slicing and dicing machines help meet this demand by delivering speed, accuracy, and consistency at scale.

Jay Bhavani Mechanical Works brings strong expertise in designing reliable food processing machinery that supports high productivity and consistent quality.

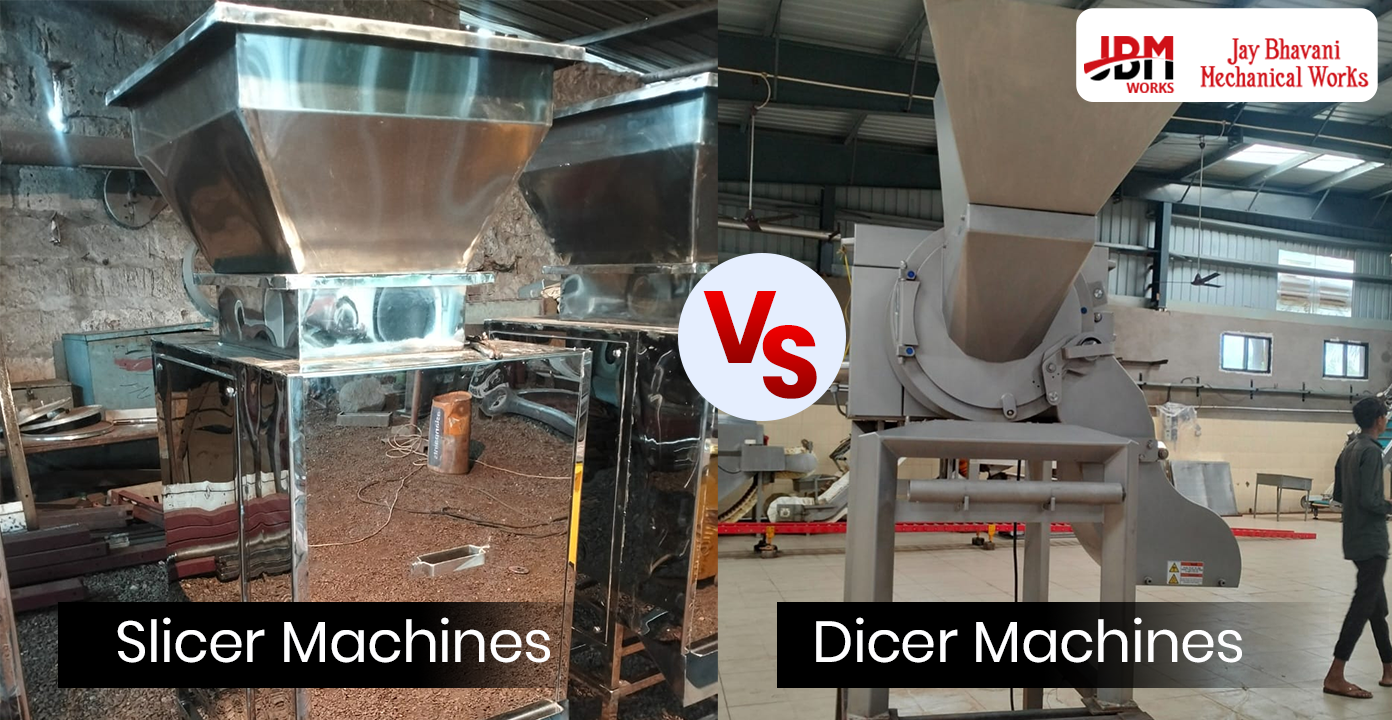

A slicer machine is designed to cut food products into uniform slices with controlled thickness. It works by passing the product through sharp rotating or reciprocating blades that slice it cleanly and evenly. The thickness of the slices can often be adjusted depending on the product requirement.

Slicer machines can produce different slicing styles such as round slices, flat slices, or adjustable-thickness cuts. They are commonly used for vegetables like potatoes, onions, cucumbers, carrots, and fruits, as well as for cheese and other food items. In food processing units, slicers are widely used for snack preparation, pre-processing before cooking or drying, and ready-to-pack food products where appearance and consistency are critical.

A dicer machine is used to cut food products into uniform cubes, strips, or precisely sized pieces. The machine works by pushing the product through a grid of blades that cut it in multiple directions simultaneously, ensuring consistent shape and size.

Dicer machines are ideal for producing cube cuts, strip cuts, and evenly sized diced pieces. They are commonly used for vegetables such as potatoes, carrots, onions, capsicum, and fruits used in salads, frozen foods, and ready-to-eat meals. In large-scale food processing, dicer machines are essential for high-volume operations where speed, accuracy, and uniformity are required.

| Comparison Parameter | Slicer Machine | Dicer Machine |

|---|---|---|

| Type of Cut Produced | Produces flat or round slices with consistent and adjustable thickness, ideal for uniform presentation. | Produces cubes, strips, or evenly sized diced pieces with precise dimensions. |

| Output Shape & Appearance | Focuses on surface-area cuts that enhance visual appeal and are suitable for layered or fried products. | Delivers uniform shapes that support portion control and consistent cooking results. |

| Processing Method | Uses single-direction cutting with sharp blades for straightforward slicing operations. | Uses multi-directional blade grids to cut products simultaneously in multiple planes. |

| Speed | Generally faster for straight cuts, making it efficient for simple, repetitive slicing tasks. | Slightly slower per unit due to complex cutting, but efficient for structured and precise outputs. |

| Capacity & Volume Handling | Suitable for medium to high volumes where slicing is the primary requirement. | Ideal for large-scale operations needing consistent diced output at high volumes. |

| Product Versatility | Best for vegetables, fruits, and food items that require thin or uniform slices. | Best for products that need uniform cubes or strips for ready-to-eat or frozen foods. |

| Space & Installation Needs | More compact design, requiring less floor space and simpler installation. | Requires slightly more space due to cutting grids and feeding mechanisms. |

| Operational Complexity | Easier to operate and maintain with fewer cutting components involved. | More complex operation due to multiple blades, requiring careful alignment and maintenance. |

The demand for sliced and diced food products has grown significantly with the expansion of organized retail, food service chains, and ready-to-eat food segments.

Retail and food service demand:

Supermarkets, hotels, restaurants, and catering services prefer pre-cut vegetables and fruits to reduce preparation time and maintain consistency. Sliced products are commonly used for fresh retail packs, while diced products are favored for cooked and processed foods.

Ready-to-cook and frozen foods:

Export and bulk supply requirements:

Changing customer preferences: Modern consumers value convenience, hygiene, and uniform appearance. This has increased the demand for machine-cut sliced and diced products over manual processing.

Slicer machines are widely used where consistent thickness and visual appeal are important.

Dicer machines are essential in operations where uniform shape and size are critical for cooking and packaging.

When comparing slicer and dicer machines, output and efficiency play a crucial role in equipment selection.

Selecting the right slicing or dicing machine depends on your production goals, product type, and long-term business plans.

With deep industry experience, Jay Bhavani Mechanical Works helps food processors select machines that match product requirements, capacity needs, and operational efficiency.

Proper maintenance and hygiene practices are essential to ensure consistent performance, food safety, and long equipment life.

Jay Bhavani Mechanical Works is a trusted manufacturer of food processing machinery, offering dependable solutions for slicing and dicing applications. The company provides robust, long-lasting machines designed for consistent performance in demanding processing environments. With the ability to deliver custom-built solutions, Jay Bhavani Mechanical Works supports food processors with equipment tailored to specific products and capacity needs. Backed by strong after-sales service, technical support, and industry expertise, the company has earned a reputation as a reliable partner for food processing units across various scales of operation.